HOW HOOKLESS MAKES YOU FASTER

Zipp’s hookless road rim profile (tubeless straight side) is a vital component of Zipp’s Total System Efficiency technology. Hookless is the next evolution for road wheel in Zipp’s relentless pursuit of our sole mission: Making You Faster.

This page explains the basics of Zipp’s hookless rim profile, how it works, and how it is a vital component of Total System Efficiency (TSE).

Why Hookless is Better

More predictable/consistent compaction means stronger rim = higher impact resistance

With Zipp’s manufacturing process, a hard-tooled tire bed has a controlled thermal expansion while molding. This allows us to dial in the laminate to the fraction of a millimeter for ideal compaction at full cure. This results in a material density that is more durable with a higher impact resistance.

Optimized fiber-to-resin ratio in the laminate = lighter rim

The ability to use hard tooling throughout the manufacturing process allows Zipp to dial in the amount of resin that flows and is purged during the molding process. This results in the ideal fiber-to-resin ratio that gives the best strength to weight ratio. This optimization allows Zipp to place the optimal amount of material according to need, resulting in wheels that are hundreds of grams lighter than previous models.

Tighter tolerances mean better tire interface = safer to ride

A machined hard-tool surface allows us to control the important dimensions required by ETRTO and ISO and stay well within their tolerance range, specifically bead seat diameter, g-height, and outer diameter. Zipp’s hookless wheels are fully compliant international standards (details below).

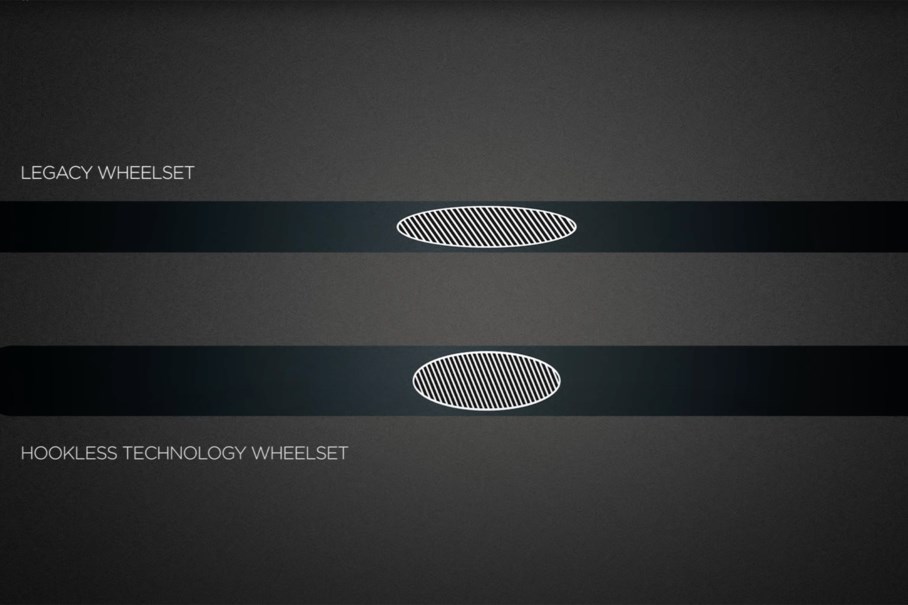

No hooks mean cleaner transition between the rim and the tire = more aerodynamic

Without the hooked section of the sidewall, the transition from the rim to the tire is streamlined, helping airflow to stay attached.

How Hookless Works

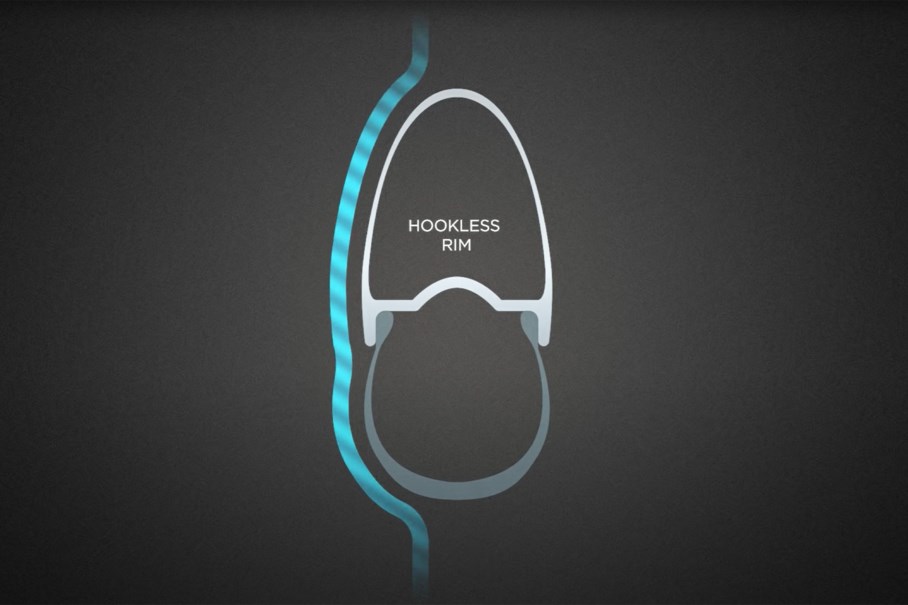

The term hookless refers to the shape of the rim at the outer diameter of the tire bed. Traditional road clincher rims have inward hooks at the rim’s edge, called crochet-type rims, where the tire bead attaches to the rim. Hookless rims have no hooks at the outer diameter of the rim.

On a standard clincher, the overhang hook and tire bead interface keep the tire on the rim. Tubeless-ready tires have strong and stiff beads that create an air-tight seal between the rim and tire. The tire relies on the stiffness of the tire bead to keep it attached. When putting on a tubeless tire, the beads sit in the well of the rim, and when installed, the bead moves up to the bead seat diameter, locking it into place with an air-tight seal.

Then air pressure goes to work. When you first inflate a tubeless tire onto a Zipp hookless rim, you hear several pops as the tire bead seals to the rim.

Confidence of International Standards

Zipp hookless wheels meet the current industry standards for the dimensions that control tire retention. The tire manufacturer determines their tire’s compatibility with those standards. Zipp actively collaborates with tire manufacturers within ISO and ETRTO committees to develop clear international standards for tubeless road tires.

International standards require Zipp hookless wheels to not inflated higher than 73 psi (5 bar). Zipp designed the wheels to be fastest at pressures below that limit. Please follow the tire manufacturer’s minimum inflation pressure recommendations marked on your tire.